How is the adhesion of UV no-base coat varnish, and how can adhesion be improved?

One of the core advantages of UV primerless varnish is its strong adhesion. It is designed to form a robust bond directly on various substrates without requiring a primer coat, which is its key distinguishing feature from conventional UV varnishes.

Specific adhesion performance and influencing factors are as follows:

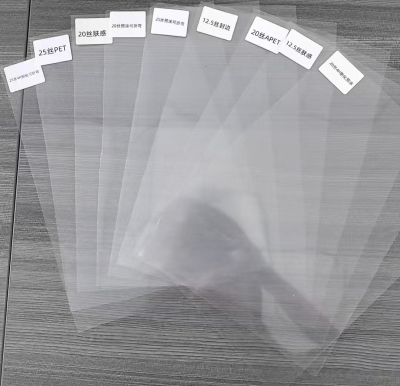

Basic Adhesion Level: Adhesion to common substrates (such as paper, PVC, PET, ABS, etc.) generally meets standards, fulfilling the fundamental requirements of most printing and packaging applications. After curing, peeling or flaking is unlikely to occur.

Key Influencing Factors:

1. Substrate Characteristics: Surface cleanliness (e.g., oil contamination or dust reduces adhesion) and smoothness (excessively smooth substrates may require light treatment) directly impact adhesion.

2. Coating Formulation: Different brands of UV primerless coatings vary in resin and additive ratios, resulting in tailored adhesion properties (e.g., some products are specifically optimized for PET adhesion).

3. Curing Conditions: Insufficient curing energy or uneven irradiation may result in incomplete curing of the coating, thereby compromising adhesion. Conversely, excessively high energy levels can increase internal stress and reduce bonding effectiveness.

Practical Application Verification: When applied under compliant conditions (e.g., substrate cleanliness, appropriate curing parameters), adhesion can be verified via tape tests (e.g., no significant peeling with 3M tape) and withstand routine operations such as friction and folding.

The key to enhancing the adhesion of UV primerless topcoats lies in optimizing substrate pretreatment, matching the topcoat formulation, and ensuring curing conditions meet standards. Specific actions can be taken in the following three areas:

1. Substrate Pretreatment: Addressing “Surface Issues”

• Thoroughly clean the substrate: Wipe the surface with solvents like alcohol or isopropyl alcohol to remove contaminants such as grease, dust, and release agents, preventing these impurities from interfering with the bond between the coating and substrate.

• Enhance substrate surface activity:

◦ For smooth substrates (e.g., PET, PP), employ corona treatment (to increase surface tension) or light abrasion (to create micro-roughness) to enhance physical anchoring of the coating.

◦ If moisture is present on the substrate, pre-dry it thoroughly (especially for absorbent substrates like paper or wood) to prevent adhesion loss due to moisture evaporation after curing.

2. Varnish Selection and Application: Ensuring Compatibility

• Select Targeted Varnish Formulations: Choose specialized UV primerless varnishes based on substrate type (e.g., plastic, metal, paper). For difficult-to-bond substrates like PP, use varnishes containing polar resins or adhesion promoters.

• Control Varnish Application Parameters:

◦ Apply uniform thickness (typically 3-10μm). Excessive thickness may cause cracking or peeling due to internal stress; insufficient thickness may result in uneven coverage and compromised adhesion.

◦ Avoid multiple applications (unless product permits). Repeated coating may cause interlayer adhesion issues.

3. Curing Conditions: Ensure “Complete Cure”

• Match curing energy and speed: Adjust UV lamp power (e.g., 8-12KW) and conveyor belt speed per varnish manufacturer's recommendations. Ensure curing energy meets varnish requirements (typically 80-150mJ/cm²). Avoid insufficient energy causing “surface dry but not fully cured” or excessive energy leading to substrate warping and varnish brittleness.

• Ensure uniform curing: Inspect UV lamp angles to prevent exposure gaps at edges or creases. Add auxiliary UV lamps if necessary to guarantee complete curing across the entire coating surface.