What is PET Film Printing?

In today’s world of superior packaging, digital signage, and product labeling, one cloth has won growing interest for its versatility and performance—PET film. But what precisely is PET movie printing? How does it work, and why is it so extensively used throughout industries from meals to electronics?

This article objectives to grant a complete overview of PET movie printing, such as what PET movie is, how it is printed, what printing applied sciences are used, and the many approaches it is remodeling industries.

What is PET Film?

PET stands for Polyethylene Terephthalate, a kind of polyester cloth extensively used in the manufacturing of packaging films, plastic bottles, and containers. In movie form, PET is recognized for its:

High tensile strength

Excellent transparency and gloss

Good dimensional stability

Chemical and moisture resistance

Recyclability

What is PET Film Printing?

PET movie printing refers to the manner of making use of ink, toner, or different printable fabric onto PET movie to create images, text, or designs. The printed PET movie is then used in a large vary of merchandise such as:

Product labels

Flexible packaging

Overlays for electronics

Window decals

Decorative or promotional signage

Transfer movies for textiles

Because PET movie has a smooth, non-porous surface, printing on it requires specialised inks and applied sciences that make sure robust adhesion, colour accuracy, and durability.

Common PET Film Printing Methods

There are numerous applied sciences used to print on PET film, every with its very own benefits relying on the utility and manufacturing scale.

1. Screen Printing

Ideal for: Large or thick ink layers, long lasting prints.

Process: A mesh display is used to switch ink onto the PET movie thru a stencil.

Benefits: High durability, brilliant color.

Limitations: Less appropriate for small textual content or specified images; slower for high-volume runs.

2. Gravure Printing

Ideal for: High-volume packaging materials.

Process: Uses engraved cylinders to switch ink onto the film.

Benefits: Excellent photograph quality, high-speed production.

Limitations: High preliminary setup cost; mostly for lengthy runs.

3. Flexographic Printing

Ideal for: Labels, packaging.

Process: Flexible printing plates switch ink to the PET movie by rotating cylinders.

Benefits: Fast, adaptable to unique substrates.

Limitations: May no longer provide the identical high-definition consequences as gravure or digital.

4. Digital Printing

Ideal for: Short runs, personalization.

Process: Inkjet or laser printing without delay on the movie except printing plates.

Benefits: Fast setup, variable statistics printing, low waste.

Limitations: Slower speed; ink adhesion can be a project besides ideal floor treatment.

5. Thermal Transfer Printing

Ideal for: Barcode labels, variable data.

Process: A heated printhead transfers ink from a ribbon onto the PET film.

Benefits: Durable, clear textual content and barcode output.

Limitations: Slower for full-color applications.

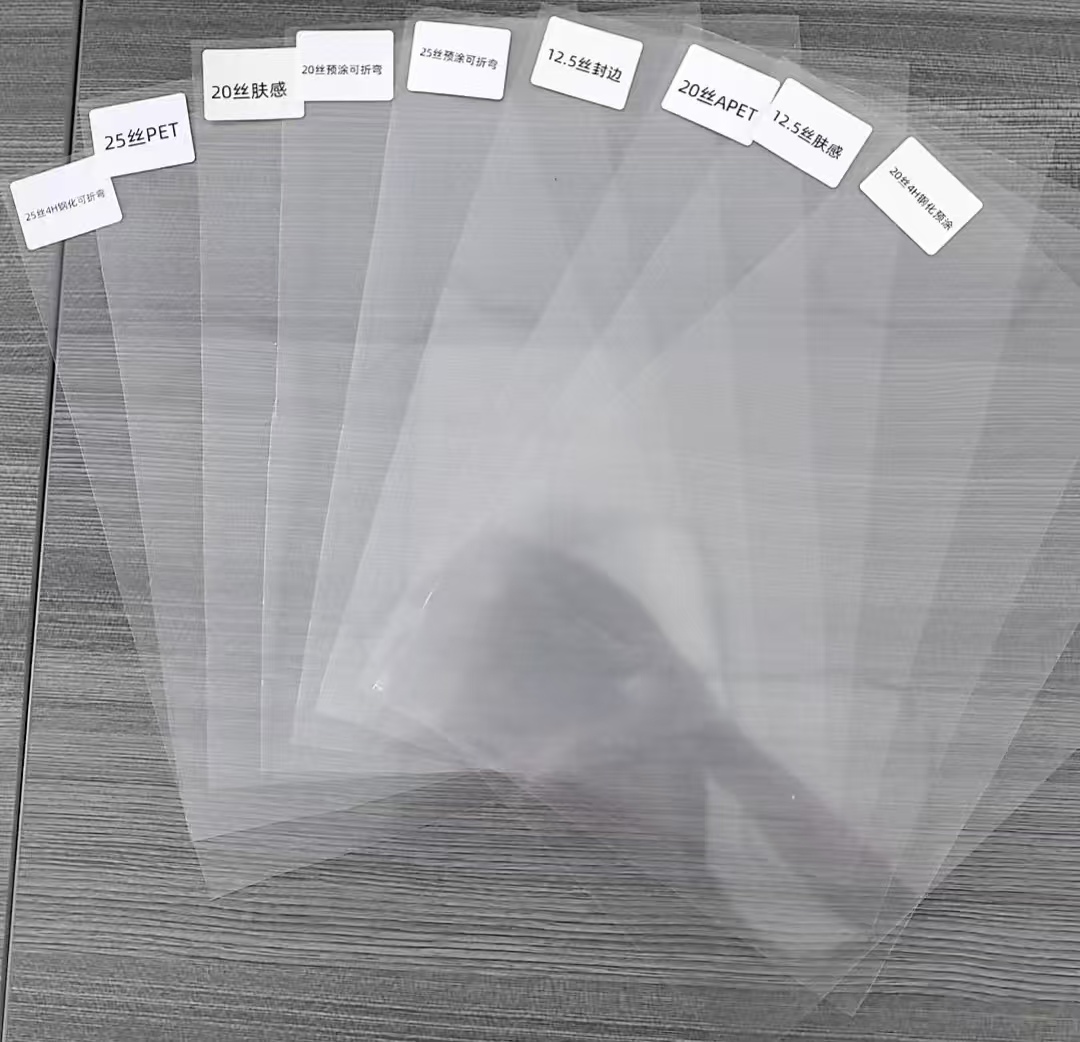

PET movie is on hand in a number of thicknesses and floor finishes (matte, glossy, frosted), making it appropriate for exclusive printing techniques and end-use applications.

Surface Treatment and Ink Adhesion

Because PET movie has a low floor energy, it need to frequently be handled to make certain acceptable ink adhesion. Common floor redress include:

Corona Treatment: Uses electrical discharge to expand floor energy.

Flame Treatment: Passes the movie over a flame to prompt its surface.

Plasma Treatment: Employs ionized fuel for high-energy floor activation.

Chemical Primers: Coatings that decorate ink anchoring.

Choosing the proper mixture of floor therapy and ink kind (e.g., UV-curable, solvent-based, or water-based) is necessary for high-quality, long lasting results.

Applications of PET Film Printing

PET movie printing is used throughout many sectors. Here are some of the most frequent applications:

1. Flexible Packaging

Snack bags, frozen meals wrappers, beauty pouches.

PET affords outstanding barrier houses and printability for vivid branding.

2. Labels and Stickers

Used in beverage bottles, private care products, and pharmaceuticals.

PET movie labels are water-resistant, tear-proof, and well suited with high-speed software machinery.

3. Electronics and Automotive Overlays

Used for manage panels, membrane switches, and contact interfaces.

Durable printing is quintessential to stand up to temperature and abrasion.

4. Textile Transfers

PET movie is used as a provider for designs that are later heat-transferred onto fabric (e.g., T-shirts).

PET movie permits vibrant, full-color prints that stay bendy on clothing.

5. Advertising & Display

Banners, window clings, flooring graphics.

PET is long lasting adequate for each indoor and out of doors use.

Advantages of PET Film Printing

High Print Clarity: PET’s easy floor allows sharp, high-resolution printing.

Durability: Prints are resistant to moisture, chemicals, and bodily wear.

Eco-Friendly Options: PET movies can be recycled and are regularly BPA-free.

Customizability: Available in transparent, opaque, matte, or smooth finishes.

Versatility: Can be mixed with different substances (e.g., aluminum) for hybrid structures.

The Future of PET Film Printing

With the upward jab in demand for sustainable packaging and high-end digital printing, PET movie printing is evolving rapidly. Innovations include:

Bio-based PET videos made from renewable sources.

Hybrid digital/analog printing for most economical customization.

Smart packaging with QR codes or NFC printed without delay on PET substrates.

Laser-markable PET motion pictures for tamper-evident or traceable labeling.

As manufacturers are trying to find greener, smarter, and greater attractive packaging, PET movie printing continues to play a imperative function in enabling innovation.

PET movie printing is a sophisticated, multi-faceted manner that merges fabric science with superior printing technologies. Whether for developing long lasting product labels, shiny packaging, or practical digital overlays, PET motion pictures provide an unbeatable mixture of strength, clarity, and flexibility.

Understanding how distinctive printing strategies have interaction with PET movie helps producers and designers make knowledgeable selections that align with their goals—whether they’re prioritizing aesthetics, performance, or sustainability.

As the printing enterprise continues to innovate, PET movie stays a cornerstone fabric using development throughout limitless applications.