What parameters should be considered during the corona treatment process for corona-treated films? How can the surface tension of corona-treated films be improved after treatment?

During the corona treatment process of corona-treated films, the following parameters significantly affect the treatment results and require close attention and control:

Key Parameters

- Voltage and Power: These must be adjusted based on the film material and thickness. If the voltage is too low, the surface treatment will be insufficient, and the desired surface tension cannot be achieved; if it is too high, it may cause the film to overheat, age, or even rupture, while also increasing energy consumption.

- Electrode Distance: The distance between the electrodes and the film (or corona roller). If the distance is too close, sparks may penetrate the film; if too far, the discharge intensity is insufficient, resulting in poor treatment effectiveness. The distance must be precisely set based on the film type and treatment requirements.

- Treatment Speed: The speed at which the film passes through the corona treatment device. If the speed is too fast, the film surface receives insufficient discharge treatment time, resulting in inadequate treatment; while too slow a speed may cause prolonged exposure to the corona discharge, potentially damaging the film's properties. This parameter must be coordinated with voltage, power, and other parameters.

- Environmental humidity: Excessively high humidity can affect discharge stability, potentially leading to uneven treatment results; conversely, excessively low humidity may cause static electricity, posing safety risks. Environmental humidity is generally controlled within an appropriate range (e.g., 40%-60%).

- Film tension: The tension of the film must remain stable during the treatment process. Excessive tension may cause the film to stretch and deform; insufficient tension may cause the film to sag, resulting in unstable distance from the electrode and affecting treatment uniformity.

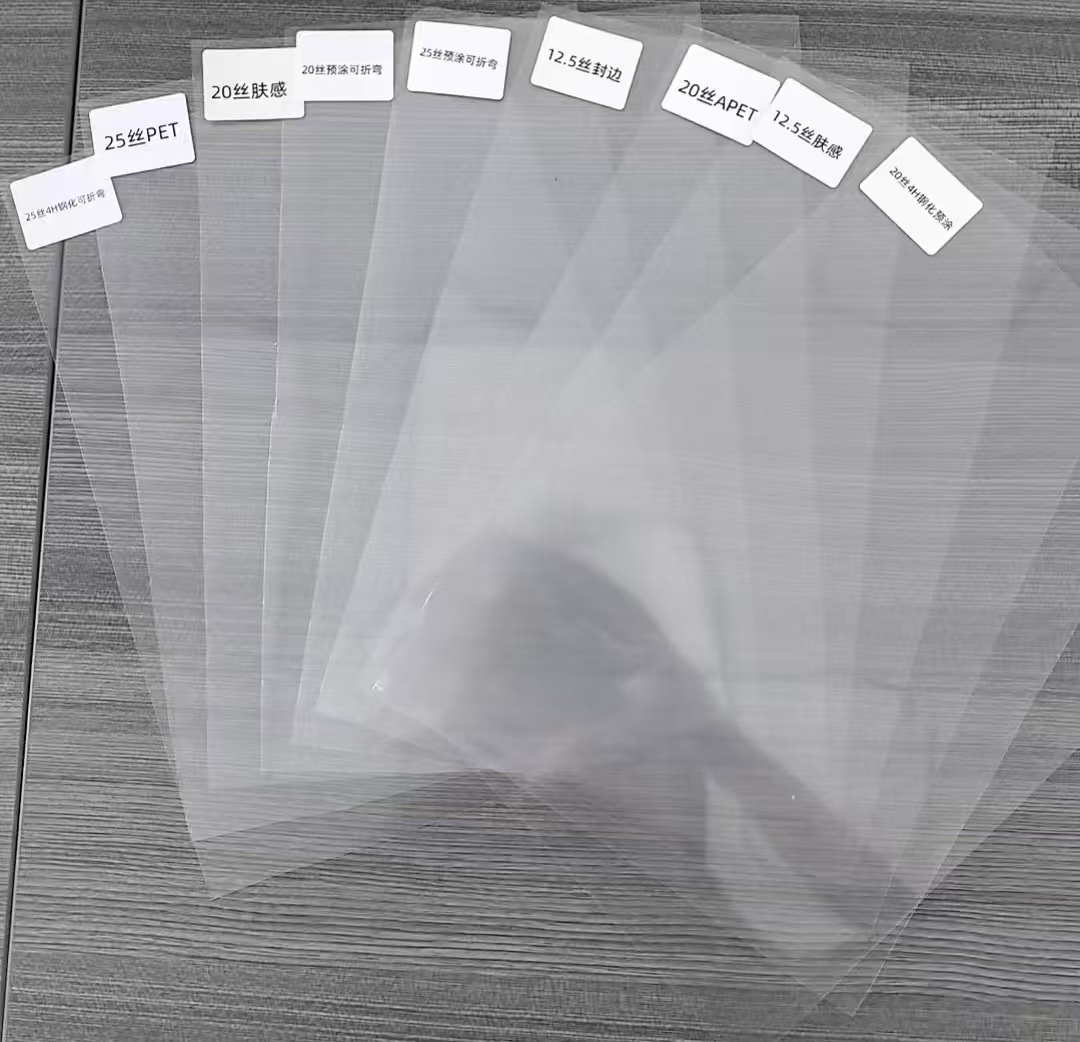

These parameters are interrelated and must be comprehensively adjusted based on the specific film material (e.g., PET, BOPP, etc.) and subsequent processing requirements (e.g., printing, lamination, etc.) to ensure stable and uniform corona treatment effects while avoiding damage to the film's inherent properties.

To enhance the surface tension of the film after corona treatment, it is necessary to optimize corona treatment parameters, control environmental conditions, and ensure the pre-treatment state of the film. The specific methods are as follows:

1. Adjust the core parameters of corona treatment

- Increase treatment power/voltage: Within the film's tolerance range, appropriately increasing the output power or voltage of the corona machine can enhance discharge intensity, promoting more thorough oxidation and cross-linking reactions on the film surface, thereby improving surface activity. However, care must be taken to avoid excessive power causing the film to overheat, age, or damage.

- Reduce electrode distance: Within the limits of avoiding spark breakdown, shortening the distance between the electrodes and the film (or corona roller) can enhance the electric field strength, improve discharge efficiency, and thereby increase surface tension.

- Reduce processing speed: Slowing down the speed at which the film passes through the corona treatment device extends the processing time, allowing the film surface to receive more thorough corona treatment and improving the treatment effect.

2. Optimize environmental and equipment conditions

- Control environmental humidity: Maintain environmental humidity between 40% and 60%. Low humidity can cause static electricity, affecting discharge stability; high humidity may weaken discharge intensity, both of which are detrimental to surface tension enhancement.

- Maintain equipment cleanliness: Regularly clean oil residues, dust, and other contaminants from the electrodes and corona rollers to prevent them from obstructing discharge, ensuring uniform and thorough corona treatment.

3. Ensure film pre-treatment quality

- Ensure thorough drying: Before treatment, ensure that the film raw material (e.g., PET chips) is thoroughly dried to avoid moisture affecting the melting state and surface properties of the film, which could indirectly impact corona treatment effectiveness.

- Clean surface: During stretching and forming processes, the film should be kept free from oil residues and impurities to ensure a clean surface before corona treatment, enabling optimal discharge performance.

Note that higher surface tension is not always better; it must be matched with subsequent processing requirements (e.g., inks and adhesives used for printing and lamination). Over-treatment may degrade film properties (e.g., increased brittleness), so parameters should be adjusted according to actual needs.