What is the production process for toughened pre-coated films? What is the market prospect?

The production process of toughened pre-coated film is mainly centered on substrate treatment, adhesive layer coating and curing, quality inspection and other aspects of the process, the specific steps are as follows:

Raw material preparation

Select PET film that meets the requirements of the substrate, its thickness, transparency and other parameters need to be determined according to the product use.

Prepare EVA hot melt adhesive and other adhesive raw materials, to ensure that its composition and performance is stable to ensure that the adhesive effect after lamination.

Surface cleaning

Clean the surface of PET substrate by special equipment (such as porous electrostatic rollers, adsorption strips, etc.) to remove dust, impurities and so on.

With the dust removal fan and pipeline, the cleaned dirt will be discharged in time to avoid secondary pollution and ensure the surface of the substrate is clean, laying a good foundation for the subsequent adhesive application.

Infiltration pressure baking

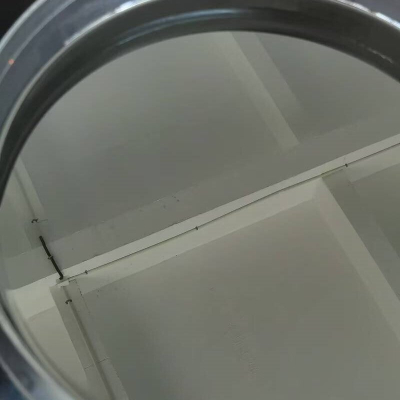

Immerse the PET substrate into the immersion treatment box containing glue liquid, so that the surface of the substrate is uniformly attached to a layer of glue.

Adjust the thickness of the adhesive material by utilizing the electric pusher, scraping motor and other equipments to ensure the uniformity of the coating.

Subsequently, the substrate will be sent to the drying treatment box, through the cycle of drying (such as hot air drying) to remove the moisture or solvent in the adhesive layer, to complete the initial adhesive attachment.

Single-spray hot drying

Secondary adhesive attachment is carried out on the surface of the semi-finished pre-coated film, where the thickness and uniformity of the adhesive layer is further adjusted by means of spraying, for example.

With the help of heat circulation drying system (such as air inlet pipe rack, intercepting heat preservation box, etc.), so that the adhesive material better attached to the surface of the substrate, to enhance the adhesive layer and the bonding of the substrate.

Thickness measurement and collection

Measure the thickness of the pre-coated film with professional testing equipment to ensure that the product thickness meets the standard.

The qualified pre-coated film is processed by winding, cutting, etc., and finally organized and packaged by the collection equipment to complete the production of finished products.

The whole process pays attention to the control of parameters (such as temperature, thickness of adhesive layer, drying time, etc.) to ensure that the transparency, adhesion, abrasion resistance and other key properties of the tempered pre-coated film are up to standard.

Toughened pre-coated film market has a broader outlook, the following is a specific analysis:

- Significant growth in market size: The global pre-coated film market shows strong growth momentum, and the market size is expected to expand significantly in 2025. In China, the precoated film market is developing rapidly, and is expected to account for a certain proportion of the global market share by 2025, and realize a high compound annual growth rate.

- Expanding application areas: In the packaging field, due to its good printing performance, chemical resistance and environmental characteristics, it occupies an important position in the packaging applications of food, beverage, pharmaceutical and other industries, and with the development of e-commerce, the demand for pre-coated film for packaging is expected to further increase. In the electronics industry, pre-coated film is used for the surface treatment and protection of circuit boards, cell phone screens and other components, with the trend of thin and light electronic products and new energy vehicles, smart homes and other emerging areas of the rise, its demand is growing. In the field of construction, the pre-coated film has excellent weather resistance, corrosion resistance and decorative properties, to meet the high requirements of the construction industry on the performance of the material, with the accelerated process of urbanization and energy-saving requirements of the building to improve the application of broad prospects.

- Stronger policy support: national policy support for the development of toughened pre-coated film industry provides a strong guarantee, such as “Made in China 2025” and “Green Packaging Industry Development Plan” and other policy documents clearly proposed to promote the green packaging materials, intelligent upgrading, pre-coated film as an important part of which will benefit from this trend.

- Technological innovation drives development: the application of new environmentally friendly materials and advanced production processes, so that the performance of pre-coated film products has been significantly improved, while reducing production costs. For example, the application of water-based coatings, nanotechnology, etc., will continue to improve the performance of pre-coated film, expanding its application areas.

- Environmental protection demand provides opportunities: with the global environmental awareness, the demand for environmentally friendly pre-coated film is rising. Increasingly stringent environmental regulations also promote the precoated film industry to green, low-carbon direction, environmentally friendly precoated film products are expected to gain a larger market share.