corona film

Good adaptability to printing

Excellent lamination fastness

Improvement of surface abrasion and corrosion resistance

Protecting the original properties of the film

high degree of transparency

Good flatness

Stable physical properties

environmental character

high efficiency

- Good printing adaptability: the surface can be improved, so that the ink can adhere better, the printing pattern is clear, firm, bright colors, not easy to fade, peeling.

- Excellent composite fastness: when composite with other materials, it can form strong bonding force to ensure the quality and stability of composite products, such as composite film for food packaging.

- Improvement of surface abrasion resistance and corrosion resistance: the change of surface structure enhances the ability of the film to resist friction and chemical erosion, and prolongs the service life.

- Maintain the original performance of the film: improve the surface properties at the same time, can better retain the physical and chemical properties of the plastic film itself, such as transparency, flexibility, barrier properties.

Corona film in addition to the just mentioned good printing adaptability, excellent composite fastness, improve surface abrasion and corrosion resistance, to maintain the original performance of the film and other characteristics, there are also some of the following features:

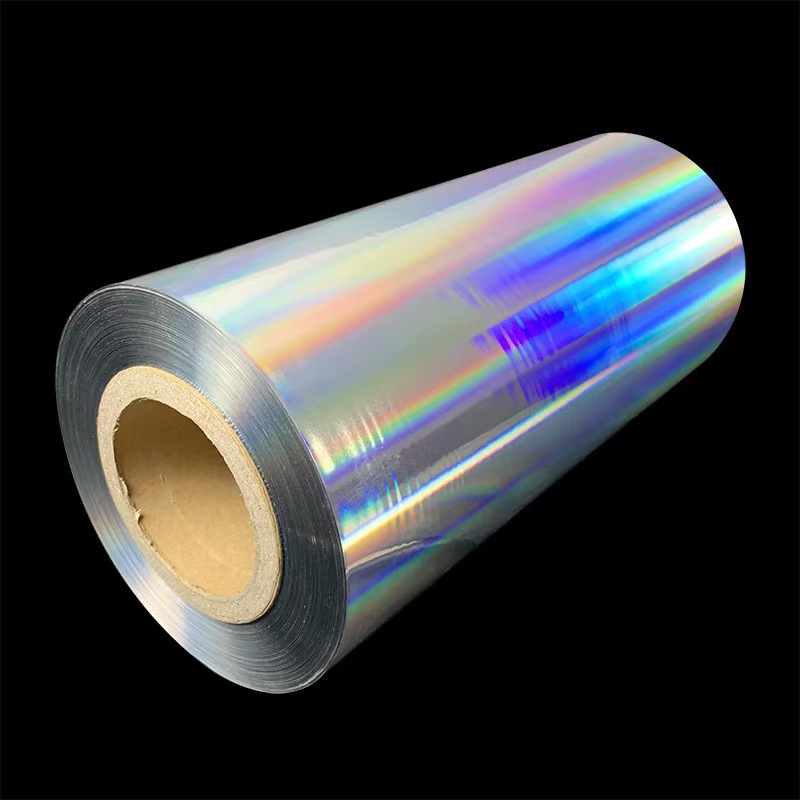

- High transparency: corona treatment usually does not have a significant impact on the transparency of the film, many corona films can maintain a high degree of transparency, can clearly show the contents of the package, which is particularly important in the field of food, cosmetics and other packaging.

- Good flatness: after treatment, the film surface flatness is high, without obvious unevenness or wrinkles, which is conducive to the subsequent printing, laminating and other processing procedures, and can ensure the consistency of product quality.

- Stable physical properties: in terms of mechanical properties, such as tensile strength, tear strength, etc., corona film can remain stable, can withstand packaging, transportation and other processes of external forces, not easy to break.

- Environmental protection: Corona treatment is a physical surface modification method, without the use of chemical solvents, reducing the pollution of the environment, in line with environmental requirements. At the same time, corona film can be recycled and reused, which is conducive to the recycling of resources.

- Efficiency: Corona treatment is fast and can treat a large number of films in a short period of time, which can meet the needs of mass production and improve production efficiency.

categorization:

- PET corona film: with high transparency, high strength, good heat resistance and barrier properties, widely used in packaging, electronics and other industries.

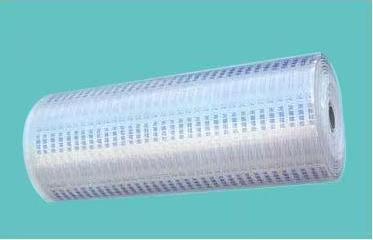

- BOPP corona film: high transparency, good stiffness, relatively low price, commonly used in printing, composite packaging, such as cigarettes, food packaging.

- PE corona film: good flexibility, low temperature resistance, more applications in food packaging, agricultural coverings, etc..

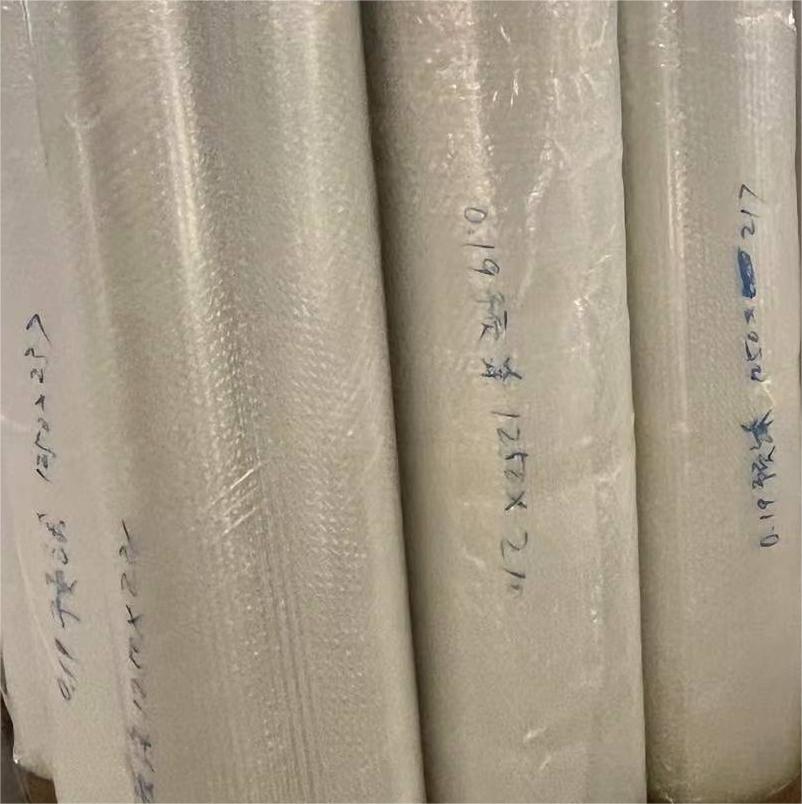

specifications:

Corona films are available in a wide variety of specifications, and common specification parameters include the following:

Thickness

- Generally 12μm, 15μm, 18μm, 20μm, 25μm, 30μm, 35μm, 40μm, 50μm, 75μm, 100μm, etc. Different application scenarios require different thicknesses, e.g., BOPP corona film for packaging cigarettes is commonly used with 18μm or 20μm, and PE corona film for some heavy-duty bags may be thicker.

Width

- Common 400mm, 600mm, 800mm, 1000mm, 1200mm, 1500mm, 1600mm, 1800mm, 2000mm, etc., can be customized according to the specific production equipment and the use of demand, for example, in the label printing, the narrower corona film width, such as 400mm - 600mm is more common for large-scale production of packaging bags may be For example, in label printing, narrower corona film widths such as 400mm - 600mm are common, while wider specifications may be used for large-scale bag production.

Lengths

- Usually in rolls, the length of 1000m, 2000m, 3000m, 5000m, etc., can also be cut or customized according to customer requirements, such as some small printers may choose a shorter length of rolls, while large packaging companies may use a longer length of corona film in order to reduce the number of times to change the rolls to improve production efficiency.

The above are only common specifications, the actual production of corona film specifications can be adjusted and customized according to the special needs of different users.