Printable PET film

Good bonding properties

Good appearance results

Strong protection performance

easy operation

high efficiency and energy saving

quality stabilization

wide range of adaptability

Cost savings

High security

- Good adhesion: both sides are coated with adhesive layer, which can be firmly bonded with both sides of printed materials and other materials, making the products more durable.

- Good appearance effect: it can improve the glossiness and colorfulness of the printed materials, make the graphics more three-dimensional, and also cover the surface defects of the printed materials.

- Strong protection performance: waterproof, anti-fouling, wear-resistant, folding-resistant, chemical corrosion-resistant, prolonging the service life of prints or other covered materials.

- Easy operation: only need to control the temperature, pressure and speed when laminating, no need to mix the adhesive, control the amount of adhesive applied and dry the adhesive as in the case of ready-to-coat film.

- Good environmental protection: no solvent volatilization, reducing pollution to the environment and health hazards to the operator.

Double-sided pre-coated film has multiple benefits, in addition to the previously mentioned good adhesion, good appearance, strong protective properties, easy operation and environmental protection, there are also the following advantages:

- Energy-efficient: In the process of laminating the film, there is no need for complicated processes such as on-site preparation of glue and drying, which reduces the energy consumption and time costs, and improves the production efficiency.

- Stable quality: Due to the uniform thickness and stable performance of the adhesive layer of the pre-coated film, the consistency of product quality can be ensured when laminating the film, which reduces the quality problems caused by uneven adhesive coating and other factors.

- Wide adaptability: It can be laminated with a variety of materials, including paper, cardboard, plastic, metal foil, etc., which is suitable for a wide range of product packaging and processing needs in different industries.

- Cost saving: In the long run, although the purchase cost of pre-coated film is relatively high, the comprehensive cost may instead be reduced due to its reduced glue waste, equipment maintenance cost and defective product rate.

- High safety: the absence of solvent evaporation reduces fire hazards and harmful gas concentrations in the production plant, improves the working environment, and ensures operator safety.

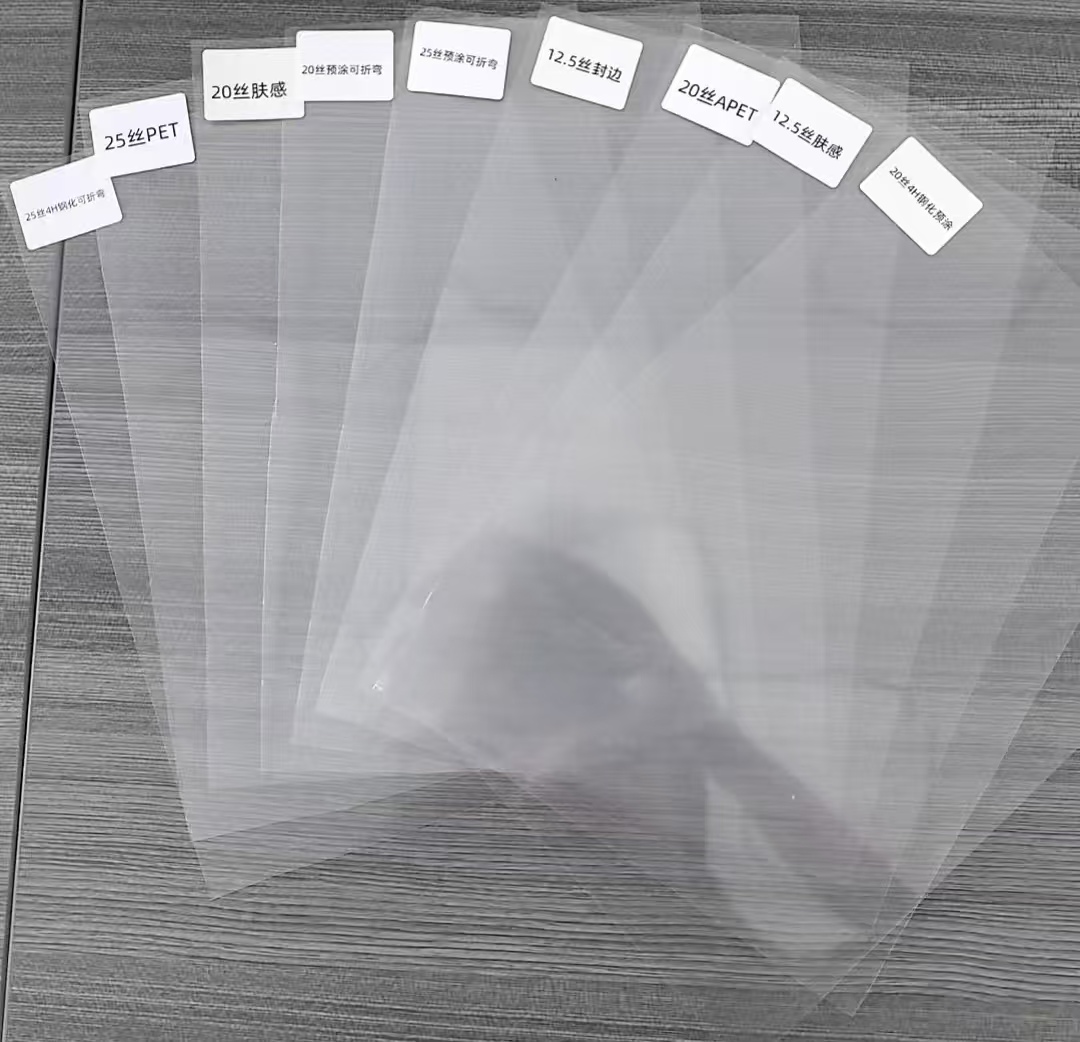

Product Specification | Printable film is divided into 10 filament, 12.5 filament, 19 filament, 25 filament and other common thicknesses, can also be customized to the required thickness, any number of meters to support customized. |

Product Applications |

|