News Center

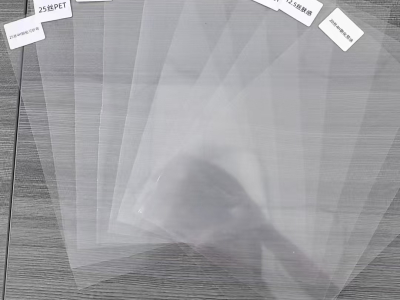

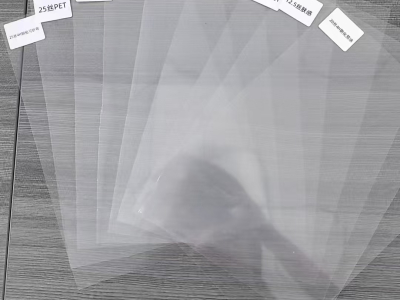

1.Material and Structural Differences PET Film: Made from thermoplastic polyester (PET) plastic, typically featuring a single-layer or double-layer structure. The outer layer is a release film to prevent dust contamination, while the inner layer contains a silicone coating to enhance adhesion. …

2025/11/18 13:25

Selecting the right UV adhesive resistant to yellowing hinges on matching the application scenario + pinpointing key performance indicators + adapting to construction conditions. Follow these 4 steps for precise selection:1. Define core requirements: Scenario and substrate• Indoor/Outdoor: For…

2025/11/06 14:25

The core production process for PET tempered pre-coated film can be summarized into four key stages: substrate pretreatment → functional coating → lamination and setting → slitting and winding. Throughout the entire process, temperature and tension must be strictly controlled to ensure stable film…

2025/10/29 14:28

Selecting UV adhesives resistant to yellowing requires comprehensive consideration of multiple factors, including application scenarios, material compatibility, curing conditions, and performance requirements.Define Application Scenarios• Long-term outdoor exposure: Such as architectural films and…

2025/10/21 13:42

Common applications of PET pre-coated films focus on two key areas: packaging protection and print enhancement, catering to high-end demands across multiple industries.• Packaging Industry: This is its core application domain, particularly suited for scenarios requiring high levels of protection…

2025/10/14 13:32

Selecting a primerless varnish requires comprehensive consideration of four core factors: substrate type, printing process, performance requirements, and budget. This ensures the varnish perfectly matches the specific application scenario.Selection Based on Substrate Type• Paper-based Substrates◦…

2025/10/07 15:04

PET film, with its diverse properties (such as high transparency, high strength, and temperature resistance), can be modified through processes like stretching, coating, and corona treatment. Its applications span multiple industries, with core common scenarios as follows:1. Packaging sector: One…

2025/09/25 15:40

Selecting the right UV adhesive resistant to yellowing requires comprehensive consideration of the following aspects:• Choose based on application scenarios and requirements◦ Optical Applications: Select UV-curable adhesives with high transparency, low refractive index, and minimal shrinkage. For…

2025/09/19 14:10

The PET pre-coated film market is poised for expansion in scale, enhanced product performance, and increased environmental sustainability, with specific trends as follows:• Market Growth: Driven by global economic recovery and industry development, demand for PET pre-coated films continues to rise…

2025/09/12 14:43

One of the core advantages of UV primerless varnish is its strong adhesion. It is designed to form a robust bond directly on various substrates without requiring a primer coat, which is its key distinguishing feature from conventional UV varnishes.Specific adhesion performance and influencing…

2025/09/04 14:17

PET silicone-coated films can be primarily categorized based on silicone coating application and functional characteristics, with common types as follows:By Silicone Coating Application- Single-sided silicone-coated film: Silicone is applied to only one side of the PET substrate, while the other…

2025/08/27 09:58

The drying time of spray-applied clear coat varies significantly depending on factors such as type, environmental conditions (temperature, humidity, ventilation), and coating thickness. It can generally be categorized into the following scenarios: Common types and their drying times- Water-based…

2025/08/19 13:38