Industry news

The core production process for PET tempered pre-coated film can be summarized into four key stages: substrate pretreatment → functional coating → lamination and setting → slitting and winding. Throughout the entire process, temperature and tension must be strictly controlled to ensure stable film

2025/10/29 14:28

Common applications of PET pre-coated films focus on two key areas: packaging protection and print enhancement, catering to high-end demands across multiple industries.• Packaging Industry: This is its core application domain, particularly suited for scenarios requiring high levels of protection

2025/10/14 13:32

PET film, with its diverse properties (such as high transparency, high strength, and temperature resistance), can be modified through processes like stretching, coating, and corona treatment. Its applications span multiple industries, with core common scenarios as follows:1. Packaging sector: One

2025/09/25 15:40

The PET pre-coated film market is poised for expansion in scale, enhanced product performance, and increased environmental sustainability, with specific trends as follows:• Market Growth: Driven by global economic recovery and industry development, demand for PET pre-coated films continues to rise

2025/09/12 14:43

One of the core advantages of UV primerless varnish is its strong adhesion. It is designed to form a robust bond directly on various substrates without requiring a primer coat, which is its key distinguishing feature from conventional UV varnishes.Specific adhesion performance and influencing

2025/09/04 14:17

PET silicone-coated films can be primarily categorized based on silicone coating application and functional characteristics, with common types as follows:By Silicone Coating Application- Single-sided silicone-coated film: Silicone is applied to only one side of the PET substrate, while the other

2025/08/27 09:58

During the corona treatment process of corona-treated films, the following parameters significantly affect the treatment results and require close attention and control: Key Parameters - Voltage and Power: These must be adjusted based on the film material and thickness. If the voltage is too

2025/08/12 14:19

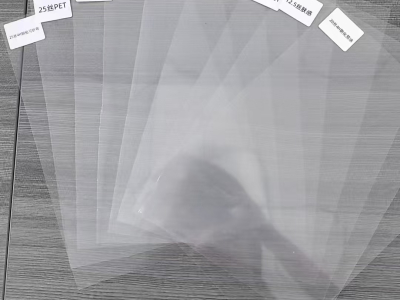

The thickness specifications of PET printable film are more diverse, and the following are common: - Ultra-thin type: the thickness is usually between 12-25μm, such as 12μm, 16μm, 19μm, 23μm, 25μm, etc., which is commonly used in the insulation layer of high-end electronic products and self-

2025/07/21 16:51

The production process of toughened pre-coated film is mainly centered on substrate treatment, adhesive layer coating and curing, quality inspection and other aspects of the process, the specific steps are as follows: Raw material preparation Select PET film that meets the requirements of the

2025/07/18 14:48

Basic Information - Full name: Polyethylene terephthalate film.- Production process: Usually the thick sheet is first made by extrusion method, and then the thick sheet is stretched into a film of uniform thickness by stretching method. Performance Characteristics - Physical properties: high

2025/06/26 16:55

In today’s world of superior packaging, digital signage, and product labeling, one cloth has won growing interest for its versatility and performance—PET film. But what precisely is PET movie printing? How does it work, and why is it so extensively used throughout industries from meals to

2025/04/17 16:07

Benefits and effects of toughened pre-coated films: Anti-scratch: the tempered film uses a special process to form a hardness layer on the surface, which can effectively prevent external hard objects from scratching the phone screen.Increase screen protection: Tempered film has a certain degree of

2024/12/11 16:14